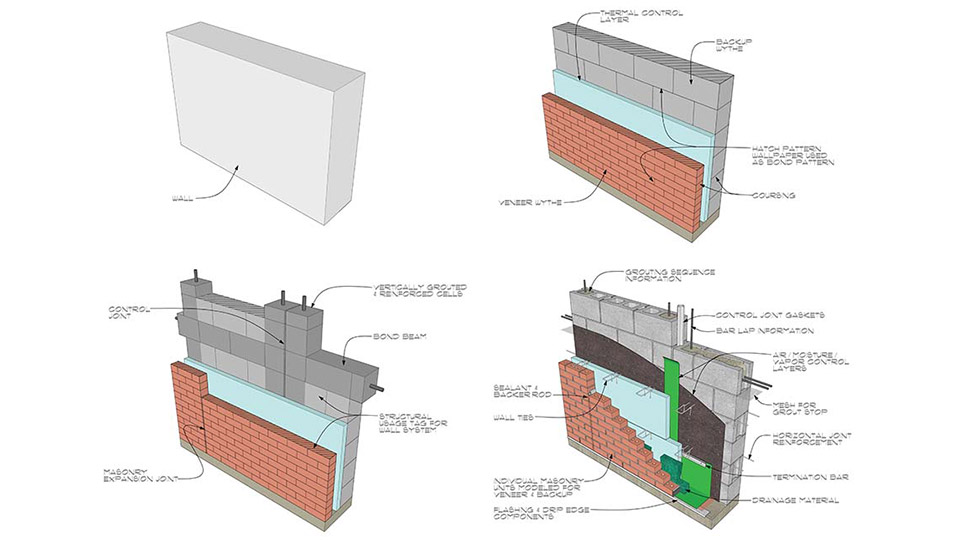

Figure 1: Masonry cavity walls, at various levels of development (LODs), have been incorporated into the 2014 LOD Specification by the BIMForum.

For this project, the bricklayers worked alongside the mechanical, electrical, and plumbing (MEP) trades to install pipe sleeves through the masonry walls as they were constructed, per the BIM model.

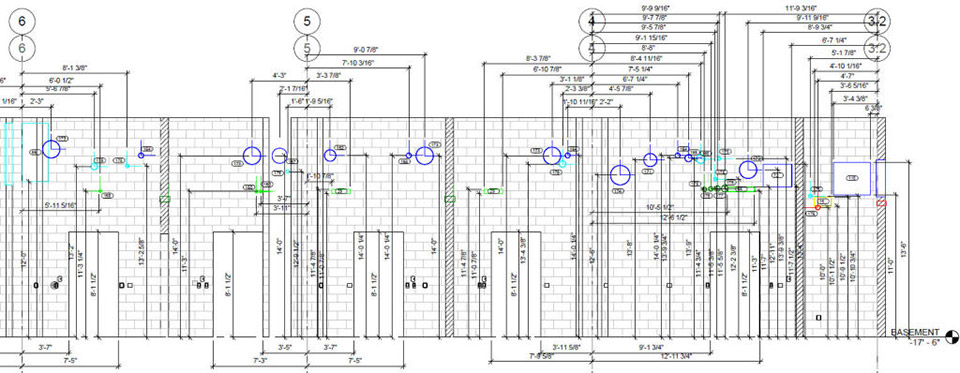

This partial elevation view of the composite model locates the MEP sleeve penetrations for the bricklayers. Each sleeve has a unique number and is color-coded per trade, as outlined in the caption to Figure 2.

In the photo above, a bricklayer installs mechanical duct sleeves at precise locations per the BIM model, as he constructs the masonry.

As the concrete masonry wall was constructed, the bricklayers installed 468 sleeves for fire protection, 231 sleeves for plumbing, 343 sleeves for water, and 10 miscellaneous sleeves. There was a total of 1537 sleeves.

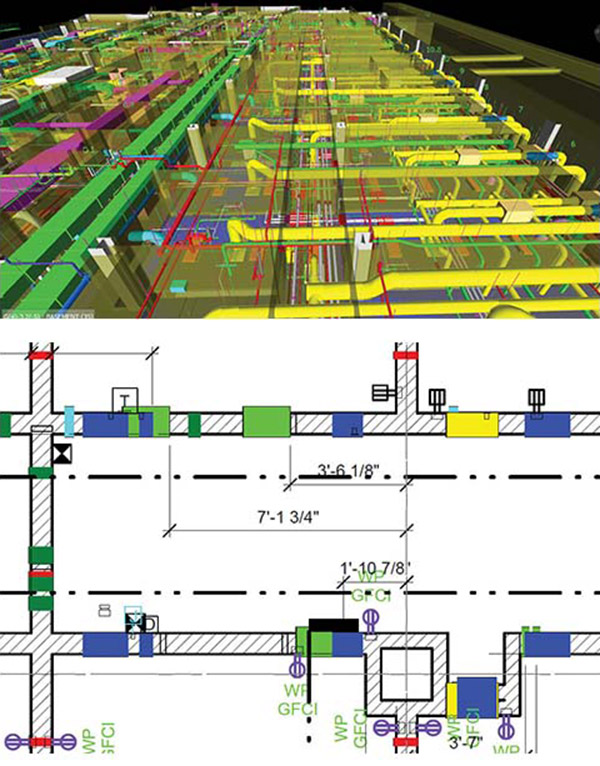

Figure 2: The coordination model in the top image shows MEP pipes and ducts passing through the masonry walls. In the lower image, a plan view of the composite model shows some of the MEP penetrations. Light green is mechanical, dark green is water, yellow is electrical, red is fire protection, blue is HVAC, and cyan is plumbing/domestic water vent.

A bricklayer (left) works in alongside a pipefitter (right) to simultaneously construct the block wall and the plumbing contained within it.

The BIM model made it possible to prefabricate the toilet room plumbing assemblies on steel strut racks to conserve space onsite. The plumbing racks were integrated into the block walls per the coordination model.

Upon completion of the masonry work, the MEP trades were able to easily install their pipes and ducts without cutting through the masonry due to the well-coordinated sleeve penetrations.