Brick Staining - Not Painting

Words: Don Foster

The Future & The Evidence “A True Trustworthy Brick Stain”

Words and Photos: Don Foster, President at Masonry Cosmetics

Sometimes, the use of brick has been compared to the life cycles of manufactured products, which experience continual changes of styles, colors and models, such as Wallpaper, Floor Tile, Drapery, Carpet, and even Cars. We understand the right and need for Brick Manufacturers to create new popular colors and sizes to strengthen their offerings and appeal. But we are also aware of the importance of maintaining and serving the history and legacy of brick, one of the best building products to this day, with thousands of years of proven field performance.

In Manufacturing, the term “cradle to grave” refers to the entire life cycle of a product, from its creation (cradle) to its disposal or end of life (grave). Brick’s life cycle is unlike those of manufactured products listed above, however, because of its endurance. Brick has so many unbelievably great benefits, one could write an entire story on those qualities alone. But let’s take a look at just one for now: manufactured brick are created maintenance-free. Granted, Brick buildings still need some maintenance. As exterior brick ages, for example, tuckpointing of the mortar may be required after many years. We have seen time and time again, however, that very minimal brickwork needs replacing on aging buildings, even ones that have lasted over 100 years.

Because these buildings do last for such an extended length of time, finding a possible match for the original brick and mortar can be challenging when the need for repairs, renovations, or architectural building design changes arise. A new window may be required, or some door fill-ins. An Architect or Builder may want to add onto a brick building while maintaining the same integrity and look of the original brick cladding. Car/brick collisions occur all the time and can create aesthetic eyesores if a comparable brick replacement in size, texture and color cannot be found. Poor brick matches are not only unattractive but can hurt property values as well as tarnish the reputation of the masonry industry.

For brick repair or new construction, several factors come into play when seeking a brick match, especially when such brick is not easily available or not available at all. Brick manufacturing mergers have posed a larger difficulty of late. When a merger happens, product lines are reevaluated, plants may focus on different kinds of production, produce fewer brick, or, sadly, close altogether. In just the last two years, a number of brick plants closed, taking millions of brick out of circulation. Other factors, such as Special Order Minimums which are on the rise, or discontinued products, add to the complexities of limited choices.

The use of a True Trustworthy Brick Stain (TTBS) has and will become even more of an integral part of brick and mortar matching going forward. To create matching brick, the first step is to locate a brick as similar as possible in Size, Texture, and Color. To create a color still closer to the brick to be matched, do a simple water test. If the brick darkens when wet, it is a good candidate for brick staining. The darker the brick gets when wet, the better.

How do we distinguish a True Trustworthy Brick Stain (TTBS) from other products? So many products claim to be a penetrating stain, yet what is in their product that causes the stain to penetrate? Some so-called Brick Stains are simply paints diluted with water. Do these products offer any long-lasting Proven Case Studies, or only provide a 25-50 year warranty with no actual proof of success? Should a watered-down acrylic or latex paint be called just that and not a Brick Stain?

Brick paint, watered down or not, is now applied daily on buildings throughout our nation. This sets the stage for disappointed home and business owners, as well as citizens of our towns and cities. Whether these individuals realize it or not, once these paints are applied to the brick of any building, the brick facing and the mortar of that structure automatically require ongoing maintenance for years to come. What can we do to avoid this poor outcome, this waste of time, energy, and private and public funds?

Similarly, can Concrete Paints affect or change the surface of a brick? While designed for use on concrete, these paints are indiscriminately used on brick. What is known about their durability on brick? Where is the research and testing on this? Do Concrete Paints create the same conundrum of endless maintenance with no resolution in sight? We strive to find answers to these questions in an ever-growing market of changing the color of brick.

A TTBS should protect the “Integrity of the Brick” which means to neither hurt nor compromise a brick that the stain is applied to. It is important that a brick remains maintenance-free after staining as it was originally designed to be. Twenty-five-year warranties should be a red flag indicating that an applied coating will need to be replaced at some point (a maintenance issue). When that happens, does all the coating (including primer, if applied) need to be removed? If so, how difficult is that?

Most stain, paint and other coating manufacturers make the claim that their product penetrates the brick surface. They can do so because most brick are absorptive, and that absorption draws the coating into the surface. Mortar is absorptive as well. Many fail to realize, however, that successfully “painting” brick is more complex than painting wood or metal.

When it comes to wood or metal, paint is not just about color. Wood also needs a protective coating to keep it from rotting, and metal needs a protective coating to keep it from corroding. As the paint lifecycle for wood or metal winds down, various methods are employed to prepare it for a new paint application. Wood or metal can be scraped, pressure washed, sanded, or stripped with chemical paint strippers. The goal is to remove as much of the old protective surface as possible before applying new paint.

Brick does not need a protective coating as metal and wood do, however, and it has different absorptive properties than wood or metal. And with brick, you aren’t dealing with just a wall, but a brick-and-mortar wall, or even better said: a wall system. When it comes time to remove paint from brick, a scraper won’t be of much help. Pressure washers or sand blasters can easily etch or damage the surface of the brick. They can also damage the integrity of the mortar joint. Paint gets embedded in the pore structure of the brick, which you might think is a good thing. But it is not, especially if the weathered paint starts to break down. Applying new paint on top of an unstable surface only compounds the problem: new paint cannot keep old paint from continuing to peel. Chemical strippers are not an easy solution either since paint embeds itself into the brick surface. Brick is manufactured in a wide variety of textures, and many of these surfaces could complicate successful chemical removal. The irony of this is that brick —manufactured to be maintenance-free for decades upon decades—painted or colored with an inferior product becomes an ongoing maintenance nightmare.

The importance of finding a True Trustworthy Brick Stain cannot be overstated. When researching the right TTBS for your project, keep an eye out for one with a proven record in the field and one with years of positive performance. If a company offers you a 25-50-year warranty on their product, they should have hundreds of examples, going back for years, representing their proven successes. Look at the brickwork pictured in their current case studies. How does it compare to when it was first stained? Is it the same? Has the brick faded or lost its original color? Has the stain failed? Most importantly, has the brick been compromised? Has the originally applied stain or paint become an ongoing maintenance project with no end in sight?

Case Studies are a good source of information, but make sure they are well documented, showing before and after photographic evidence, giving full descriptions of the work originally performed, and demonstrating what the appearance of that completed project is today. Be wary of nice-looking marketing case studies with attractive photography that show great pictures but lack basic data as to when the work and what actual work was performed and what the current appearance of the completed project is.

The TTBS could be a highly valuable tool for Architects and Building Owners of all kinds. When planning building additions and matches or acceptable replacements for discontinued brick cannot be found, then staining with the right product clearly should be considered. There are two options. The first option - matching the original building’s brick via TTBS - is a scenario that we have overseen successfully time and time again. Case Study #014, pictured below, is such a project. It was finished 21 years ago. Matching brick for the addition was no longer made nor easily available. A donor brick (brick selected to be stained for a better match) was found. The donor brick were installed, cleaned and then stained to match. That completed project was rechecked in 2023 and looks as attractive today as the day it was stained.

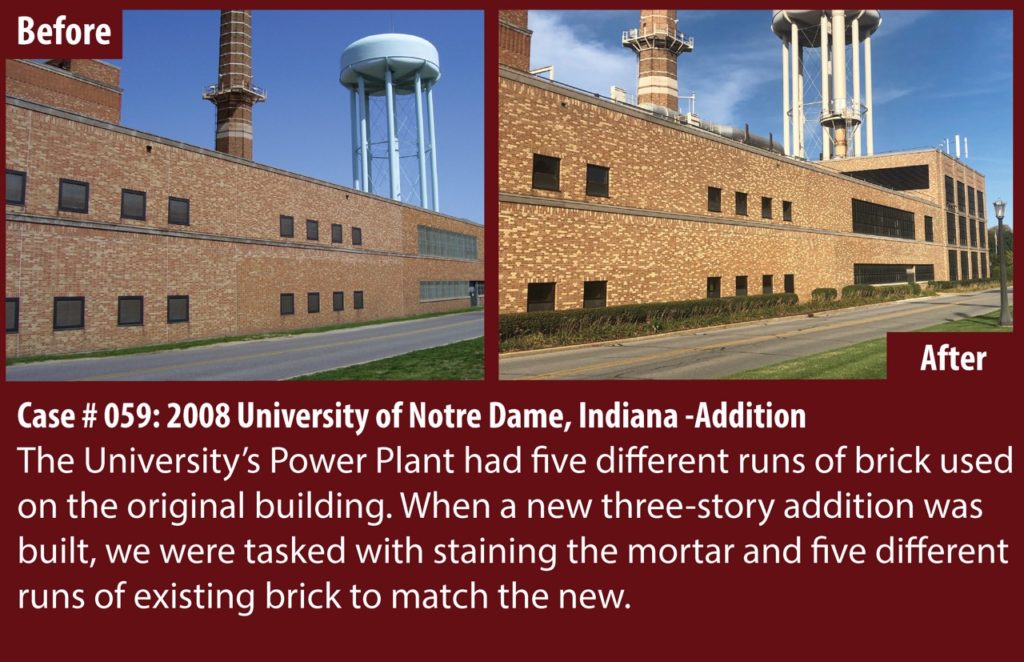

Below is an example of a project at the Power Plant of the University of Notre Dame. The original building had at least five different runs of brick, which included varying colors of mortar as well. The original brick on the building and mortar were stained to match the new three-story addition.

Brick lasts, but there are times when the color of the brick looks outdated. A Makeover - the second option - is definitely warranted. In this case study, the home or Office Building is fine structurally, but the owner wants to change the brick color. A TTBS can help here as well, as long as a water test is done and the brick are sufficiently absorptive. Absorption is the key for a project like this. Using this technique, the color of brick, mortar, block and stone can be successfully changed.

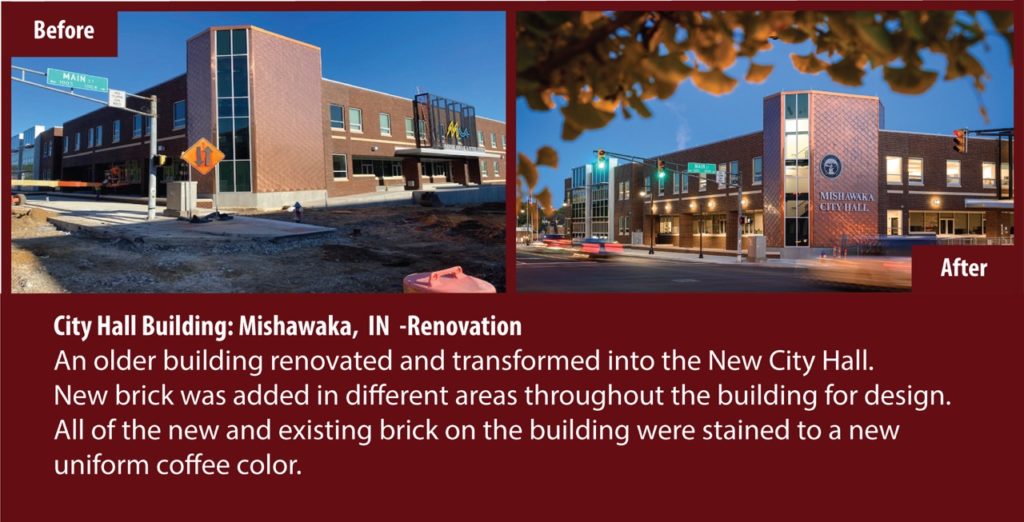

Here are two beautiful projects completed within the last two years. The first one, pictured below, is of Mishawaka’s Old Liberty Mutual Building, which was renovated for the New City Hall Building. New bricks were added in various areas for design changes, and all the new and old brick were stained a brand-new coffee color.

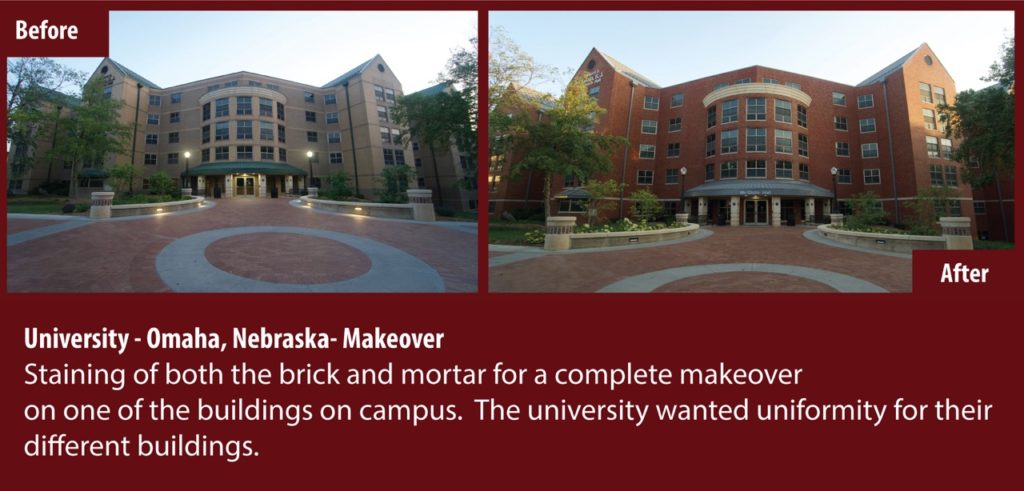

The second Makeover Project took place on the campus of a university in Nebraska. Wanting more uniformity on the campus, the University did a complete makeover on one of its buildings. All the mortar was stained first, and then the brick as well.

It’s never easy when a brick plant closes, when there is a need to match brick, yet exact matches are no longer available. But, a talented mason can assist clients with better brick and mortar matches. An accomplished professional can match repairs, fill-ins, and additions with a True Trustworthy Brick Stain. Creating great value for customers, crucial for the success of any project or business, can result in positive word-of-mouth recommendations and feedback, improved community relations, repeat projects, a valued reputation, customer satisfaction and pride in one’s work, home, office, or civic building.

The documented performance of a True Trustworthy Brick Stain eliminates concerns about fading, peeling, blistering or flaking brick. It works with absorptive brick, mortar, block or stone, allowing these materials to breathe completely, and it meets the needs of civic centers, universities, businesses and homeowners for attractive and long-lasting brick structures for years to come and, most of all, protecting the Integrity of an Industry we all work so hard to preserve.