Building Strong Foundations: CMU Specifications

Words: Alan Truong

In the dynamic landscape of construction, architects, engineers, and developers are continually seeking materials and methods that not only meet the demands of modern design but also deliver sustainability, efficiency, and safety. Amidst the many options available, structural concrete masonry units (CMU) stand out as a versatile and reliable choice for a wide range of building projects. While utilizing concrete masonry is nothing new to the construction industry, the evolving needs in durability, efficiency, adaptability, sustainability, fire safety, cost-effectiveness, and widespread availability are all met when specifying CMU, which can be an eye-opening proposition to even the most seasoned professional.

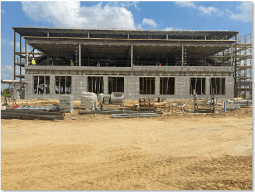

Katy Junior High School #18

Katy Junior High School #18

Katy, TX

Best Block grey block and Island Sand ground face CMU

Durability:

One of the foremost advantages of structural CMU lies in its unparalleled durability. Concrete masonry units are engineered to withstand the test of time, enduring harsh weather conditions, seismic activity, and structural stresses. Unlike traditional wood framing or lightweight materials, CMU offers superior resilience, longevity, and reduced maintenance costs over the lifespan of a building. From residential homes to commercial complexes, specifying CMU provides a robust foundation that instills confidence in both builders and occupants.

Efficiency:

In construction, time is money. Herein lies another compelling reason to specify structural CMU. The efficiency of CMU stems from its modular nature, allowing for swift and streamlined installation. Unlike poured concrete, which necessitates elaborate formwork and curing periods, CMU walls are assembled rapidly, expediting project timelines without compromising structural integrity. Moreover, advancements in the masonry code provide engineers with more efficient structural design, which can result in reduction of rebar and grout necessary in load-bearing and non-load bearing walls.

Adaptability:

Flexibility is paramount in architecture and design, and CMU offers boundless adaptability to realize diverse creative visions. Whether constructing load-bearing walls, partitions, or facades, CMU can be customized in terms of size, shape, texture, and color to accommodate unique aesthetic preferences and functional requirements. As a hand-set material, CMU allows for unique architectural expression on even the simplest of structures.

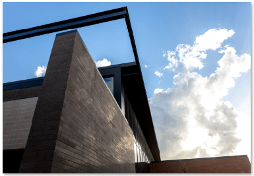

City of Houston Public Works & Engineering

City of Houston Public Works & Engineering

Houston, TX

Best Block Charcoal polished face CMU

Sustainability:

As sustainability takes center stage in the construction industry, the eco-friendly attributes of CMU cannot be overstated. Concrete, a primary component of CMU, boasts impressive recyclability, with recycled aggregates and supplementary cementitious materials increasingly incorporated into production processes. By specifying CMU, architects, and developers align with green building principles, minimizing environmental impact and promoting circularity within the construction lifecycle.

Fire Safety:

In an era marked by heightened awareness of safety standards, CMU emerges as a steadfast ally in fire protection. Unlike combustible materials such as wood framing or insulation, concrete masonry units exhibit inherent passive fire-resistant properties, effectively contain fire, and limit the spread within a structure. This crucial advantage not only enhances occupant safety but also mitigates insurance risks and regulatory compliance challenges for building owners and developers through reduced “Builders Risk” insurance premiums.

Cost-Effectiveness:

Balancing budgetary constraints with quality and performance is a perpetual challenge in construction projects. This is yet another reason for specifying CMU. Despite its litany of benefits, structural CMU remains competitively priced compared to alternative structural building systems. Moreover, the longevity and low maintenance requirements of CMU translate into significant cost savings over the lifecycle of a building, making it a prudent investment for developers seeking long-term value.

Availability:

Accessibility to materials plays a pivotal role in project planning and execution. Fortunately, CMU enjoys widespread availability across global markets, thanks to established manufacturing networks like Best Block® and local distribution. This accessibility ensures a reliable supply chain, reducing lead times and logistical complexities for construction projects of varying scales and scopes. Whether undertaking a residential renovation or a large-scale commercial development, architects and contractors can readily source CMU to meet project demands.

Successful pivots to CMU:

The versatility and benefits of specifying CMU are seen in an abundant number of successful construction projects across the country that have very different needs.

We see the use of CMU in regions prone to extreme weather events, such as hurricanes or tornadoes, where CMU emerges as a resilient building material capable of withstanding high winds and impact forces. The Gulf Coast Research Laboratory in Mississippi exemplifies this resilience, featuring a CMU-based design that prioritizes durability and safety without compromising architectural elegance.

Another example of successful CMU specification occurred with the Bexar County Fire Station in San Antonio, which was experiencing explosive growth. Once a rural community of farmers and ranchers, the community is now home to more than 5,000 residents and is growing. To keep up with the rapid development, Emergency Services District 7 needed to increase its capacity with the construction of a new two-story, 26,000 SF Fire Station on their 4-acre property. The initial goal was to design and deliver the conventional red brick fire station that has anchored communities for decades. However, when budgets forced an evaluation of other options, a single-wythe structural masonry unit was proposed, and the specification was changed to Best Block® CMU. The budget-friendly Best Brick for the front of the station and split-face CMU for the back and sides proved to be a cost-effective answer.

Bands of smooth-face CMU were carried throughout to tie the masonry materials together. In this application, Best Brik used insulation inserts to meet local energy codes. All CMUs on the exterior were manufactured with a water-repellent additive to provide lifelong resistance to moisture penetration. Best Brik, combined with the quality work from local contractors and masons, provided the look and scale for this 2-story structure that allows the building to blend well with the growing residential neighborhoods.

Bexar County Fire Station #115

Bexar County Fire Station #115

San Antonio, TX

Best Block split face and Best Brik CMU

In conclusion, the decision to specify structural concrete masonry units in construction projects transcends mere practicality; it embodies a commitment to durability, efficiency, sustainability, and safety. As architects, engineers, and developers navigate the complexities of modern design and construction, CMU stands as a steadfast ally, providing a solid foundation upon which to build the cities and communities of tomorrow. Embracing the versatility and benefits of CMU not only helps to ensure the success of individual projects but also fosters a sustainable and resilient built environment for generations to come.