Technology Trends in Masonry

Words: Matt OklevitchPhotos: Construction Robotics, Fastbrick Robotics, WUT789

Masonry is often regarded as one of the oldest trades, and although the time-honored tricks of the trade have been passed down for generations, the industry has seen numerous innovations in the tools, equipment, and technologies that assist contractors in project planning, bidding, management, and on-site installation. The integration of technology has been perhaps the most notable of those changes in recent years, with the emergence of IoT (Internet of Things), digital imaging and automation allowing for streamlined communication and safer onsite practices.

I have outlined a few of the top technology trends that can be seen in the masonry industry today, and what we can expect to see from each in the near future.

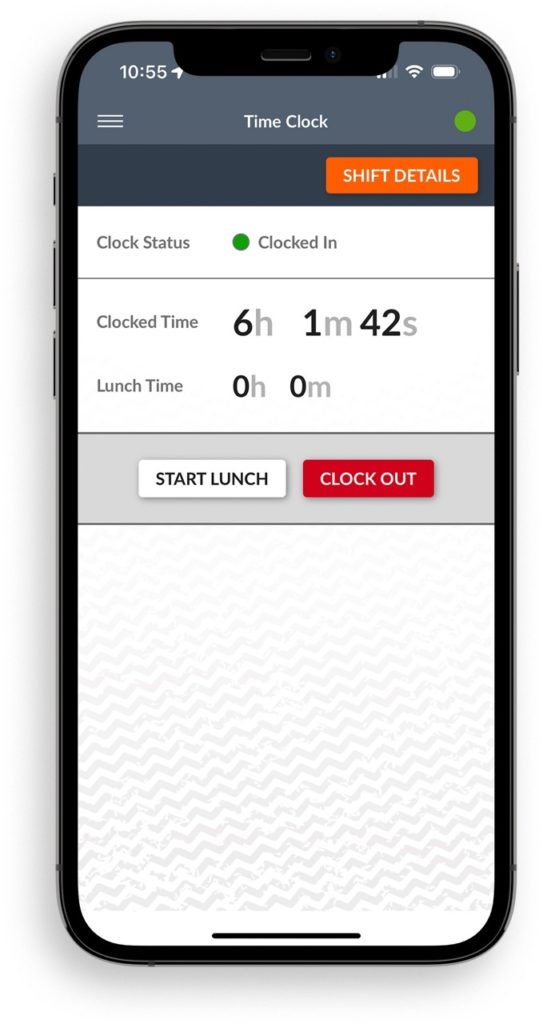

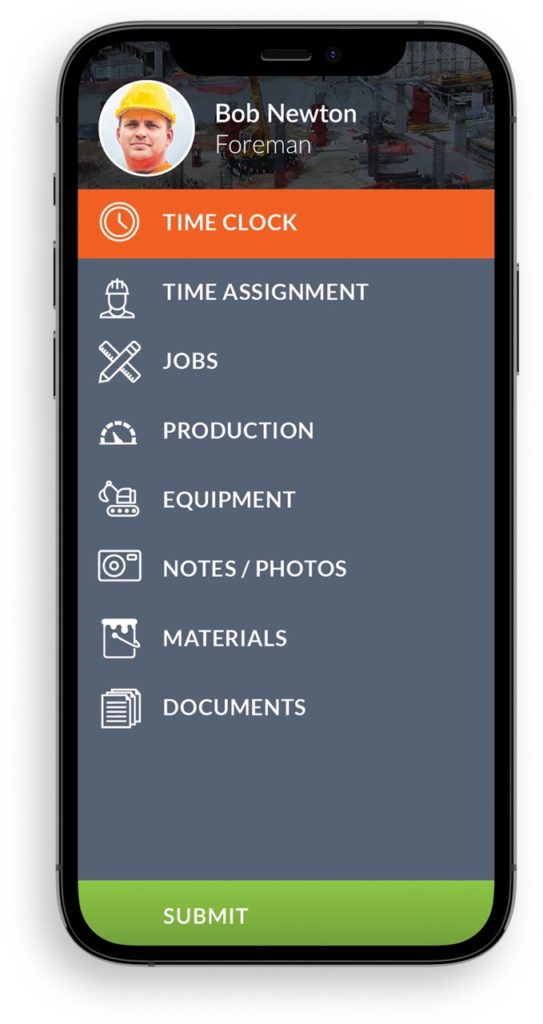

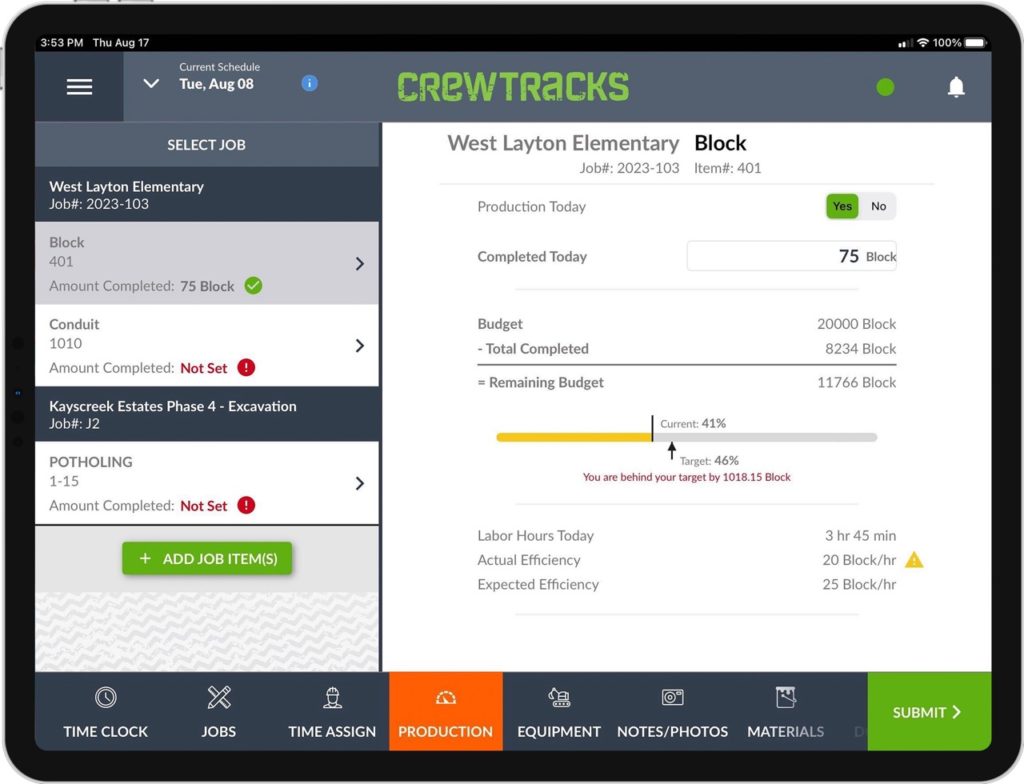

Field Management Software:

Efficiency is everything in the masonry industry, as is accurate and timely communication between the field and the office. Many contractors are leveraging the various mobile apps and software solutions available to manage projects, track materials, document work progress, and communicate with team members and clients more efficiently, and this trend will likely continue with the increase in mobile devices on job sites and a growing emphasis on user-friendly apps and software for daily reporting.

Drones and Aerial Imaging:

Drones equipped with cameras and sensors are being used for inspecting masonry structures, monitoring progress, and creating detailed surveys and 3D models of job sites. In contrast to drone technology’s initial arrival on the scene, basic consumer models are now relatively affordable, starting at just a few hundred dollars (USD) making them accessible to even the smaller contractor, while higher-end imaging and sensing equipment as well as contracted professional services are also readily available and increasing in popularity.

Building Information Modeling (BIM):

BIM software’s ability to create detailed 3D models of construction projects is an incredibly powerful tool for the mason contractor. By working with multiple layers in a simulated environment, this technology helps assist in better planning, design, and coordination with the GC, architect, and other trades, reducing errors and rework. As BIM becomes more widely adopted across the construction industry, masonry contractors and suppliers will likely face increasing pressure to integrate BIM into their workflows. This would drive more emphasis on BIM training and the use of BIM for masonry-specific applications.

Extended Reality (XR) – Augmented Reality (AR), Mixed Reality (MR), and Virtual Reality (VR):

AR and MR technologies overlay digital information onto the real-world environment, helping masons visualize designs, access instructions, and ensure accurate installation of intricate detailing, while VR simulations can provide immersive training experiences for masonry workers, allowing them to practice techniques and procedures in a safe, controlled virtual environment. Companies like Autodesk, Construction Robotics, and Argyle, are exploring ways to integrate these tools with BIM modeling.

While still an emerging technology in the masonry field, XR solutions are expected to gain traction in global user adoption in the next few years.

Robotics and Automation:

Advances in robotics and automation have allowed the masonry industry to increase safety, productivity, and consistency, while addressing labor shortages by retooling how we approach repetitive tasks such as heavy lifting and installation of materials, tuck pointing, fastening, and even demolition. While many recent robots by leading construction tool manufacturers have been uniquely focused in other industries such as Jaibot by Hiliti for the MEP trades, or Husqvarna’s DXP series of user-guided demolition bots, several companies have been focused on providing solutions tailored for the masonry industry with varying levels of automation and programmed intelligence.

Australia based company, Fastbrick Robotics (FBR), recently gained traction with their Next-Gen Hadrian X completing a factory acceptance test for deployment in the US and has also completed its largest build to date in early 2024, using a proprietary Dynamic Stabilisation Technology® (DST) and software in their automated process.

Meanwhile, U.S. based manufacture and Smart-Lifting innovator, Construction Robotics (CR), launched the next-generation of their MULE technology at World of Concrete 2024 in the MZ100, continuing to focus on hands-on-material UX (semi-automated robotics) rather than full automation, thus merging traditional masonry practices with modern IoT capabilities.

In the coming years, the masonry industry is likely to accelerate the development and deployment of both automated and semi-automated solutions for repetitive and physically demanding tasks to augment the existing workforce and attract new talent as we see increased engineering efforts and funding allocated towards these efforts from major equipment and building material manufacturers alike.

Prefabrication and Modular Construction:

Although the traditional model of masonry wall construction remains the norm for now, the drive for faster construction timelines, improved quality control, and labor shortages could lead to greater adoption of prefabricated masonry components or modular wall sections constructed off-site, as is already common in other wall systems. Custom veneers and other components can be 3D printed or built to specification, and these prefabricated or modular masonry sections can then be assembled and worked into a finished solution on site.

Technology Forecast For the Next Few Years

While some areas like drones and VR training may see some growth, the most significant emphasis and investment in the near term will likely be in utilization of construction management apps, BIM software, and automation, as the masonry industry seeks to address productivity, quality, communication, and labor challenges through technological solutions.

In summary, there’s no need to worry about cyborgs stealing masonry jobs, and an AI can’t lay to the line, but there are incredibly powerful tools at our fingertips when we embrace the technology available to masonry.