As seasonal changes bring high winds and fluctuating temperatures, masonry projects face unique challenges. These conditions can stress vertical structures, requiring reliable bracing, while temperature swings may lead to a need for masonry restoration. Additionally, maintaining a safe work environment remains crucial year-round. EZG Manufacturing’s Hog Leg Wall Bracing System, Hog Guard® Scaffold Safety Accessories, and Hog Support® for Masonry Restoration are designed to address these needs. Each product offers a targeted solution—whether reinforcing walls in windy conditions, supporting restoration work, or ensuring job site safety in varying environments. This article highlights how these systems work together to enhance safety, efficiency, and stability on your masonry projects.

Hog Legs Wall BracingMaximizing Bracing Capacity: HL400Kit and HL14EXTKIT

When embarking on a masonry project, the question of bracing capacity often looms large. Fortunately, the Hog Leg Wall Bracing System provides a clear answer. One of the most common questions we receive is about its capacity, so let’s break it down for you.

How much bracing can you get out of a Hog Leg Wall Bracing System kit?

How much bracing can you get out of a Hog Leg Wall Bracing System kit?With options like the HL400Kit and HL14EXTKIT, capable of supporting up to 400 lineal feet of wall each, the system offers scalability to meet diverse project requirements. Determining the precise amount of bracing needed is made simple through comprehensive manuals and reference charts. By considering factors such as wall height, rebar size, CMU size, and grout spacing, you can quickly ascertain the required brace length and quantity, ensuring adherence to industry standards. This system helps you meet the Standard Practice of Bracing Masonry Walls efficiently, even in conditions of high winds or during the cold months when temperature fluctuations may stress the structure.

Efficient Installation Process: Seamless Integration and Stability

Efficient Installation Process: Seamless Integration and StabilityAnother frequently asked question is:

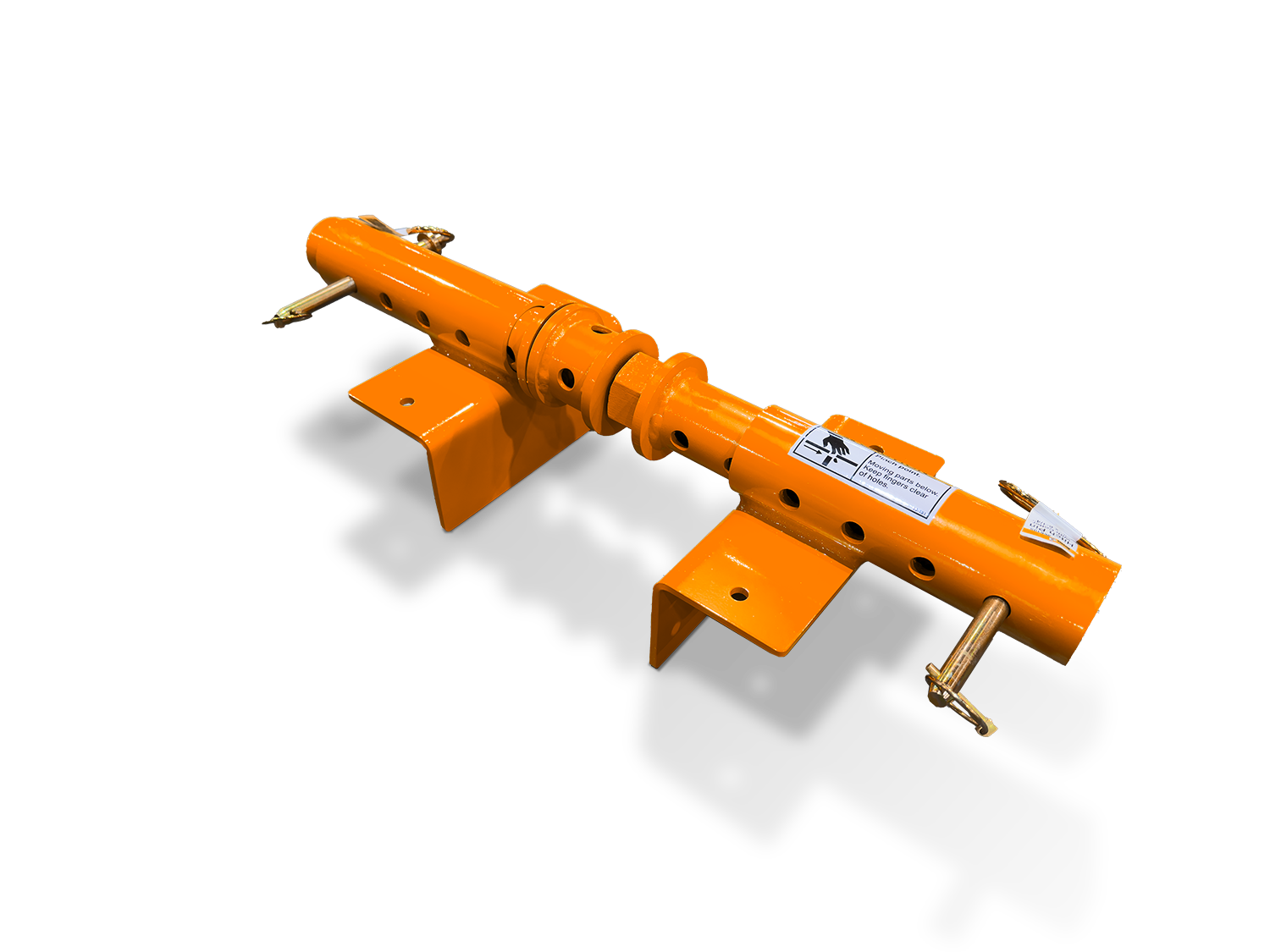

how do you install the Hog Leg wall braces?The ease of installation is a hallmark of the Hog Leg Wall Bracing System. Its straightforward design ensures efficiency without compromising effectiveness. Installation begins by interlocking two different diameter pipes using a pin, establishing a sturdy foundation for the bracing system. Additional pipe segments are seamlessly added to achieve the desired brace length, tailored to the specific dimensions of the masonry structure. Securing the brace to the wall and floor is achieved through intuitive integration with the wall bracket and footer or Deadman. Installing the wall bracket involves a simple process of inserting a T-bar into the head joint and using wedges to secure it to the wall. With the bottom pipe firmly pinned to the wall/floor bracket, the structure gains the stability it requires for long-term durability—even in gusty conditions.

Engineered for Consistency: Detailed Charts and Pre-engineered SolutionsWhile some may wonder if the Hog Leg Wall Bracing System comes with an engineered plan, the answer lies in its meticulous engineering. The system includes detailed charts within its manuals, catering to various block sizes, wall heights, rebar sizes, and grouting on-center distances. This standardized approach simplifies planning and earns the trust of contractors who recognize adherence to the Standard Practice for Bracing Masonry Walls. Whether you're bracing in windy conditions or cold temperatures, the Hog Leg System is engineered to deliver consistent results across a spectrum of masonry applications, ensuring reliability and peace of mind for professionals and clients alike.

Hog Guard Scaffold Safety AccessoriesEnhancing Scaffold Safety

Hog Guard Scaffold Safety AccessoriesEnhancing Scaffold SafetyAs the seasons shift, bringing unpredictable weather like high winds, scaffolding becomes more vulnerable. The Hog Guard® is designed to block off dangerous openings in scaffolding assemblies, such as door frames, window allowances, or large gaps that could lead to falls. This product ensures worker safety by preventing falls through unguarded spaces, particularly when conditions are less than ideal.

The Hog Guard® is customizable with interchangeable components—End Guard Assembly, Center Rail Assembly, and Stocking Bracket—all sold separately to fit your specific jobsite needs. These components are designed to work seamlessly with most existing scaffold systems, making the Hog Guard® a versatile and essential addition to any construction project. Its ready-fit design allows for quick assembly and breakdown, enhancing safety on the job site. Whether dealing with the challenges of windy weather or the cold conditions that make scaffolding more precarious, the Hog Guard® is a must-have for maintaining a safe workspace year-round.

Introducing NEW Hog Support®Precision for Masonry Restoration

Introducing NEW Hog Support®Precision for Masonry RestorationIn addition to wall bracing and scaffold safety, Hog Support® is the newest addition to EZG Manufacturing’s lineup, designed specifically for masonry restoration and repair projects. The Hog Support® tool addresses the challenges of masonry damage that can occur due to temperature fluctuations or wear over time. Whether it’s due to improperly installed wall ties, flashing issues, or structural damage, this tool ensures precise and stable support, making it an indispensable asset for professionals tackling repairs.

The Hog Support® features a versatile, adjustable design that accommodates spans up to 36 inches, offering flexible support for various restoration needs. With durable pressure-ledged angles and a 4-inch depth, the Hog Support® guarantees stability. The adjustable components—top angle, bottom angle, and center adjustment ring with locking pins—allow for precise and secure positioning, while its 932-pound weight load capacity ensures it can handle the most demanding repair tasks, even under harsh environmental conditions.

Trust EZG Masonry Reinforcement and Safety Products

Trust EZG Masonry Reinforcement and Safety ProductsIn summary, the Hog Leg Wall Bracing System, Hog Guard® Scaffold Safety Accessories, and Hog Support® for Masonry Restoration each provide essential solutions to ensure stability, safety, and efficiency on masonry projects. Whether you're dealing with the unpredictability of high winds, temperature swings that cause masonry damage, or the ongoing need to maintain a secure work environment, these systems offer reliable support to meet your needs. Each product serves a specific purpose—whether reinforcing walls with reliable bracing, safeguarding workers during hazardous conditions, or supporting tedious restoration work with precision and stability. Together, these products help professionals tackle the challenges of masonry construction and restoration, no matter the season.

Visit EZG Manufacturing's website to explore our full range of masonry equipment and safety products. Take the first step toward building with confidence, knowing you can trust EZG for top-quality solutions to meet your project’s needs.