The walls of today’s masonry buildings are becoming more complex than ever as their designs are modified to meet new energy code requirements. These modifications mean there are more components in walls than ever before, and they can all come from different manufacturers.

At its most basic, a masonry cavity wall is simply two wythes of masonry separated by a space or cavity of varying dimensions. Masonry is among the most ancient building materials, but masonry walls were solid masonry with no cavity between inner and outer wythes until reasonably recently. Also called “barrier walls,” solid masonry walls were the only types built due to materials manufacturing and building technology limitations. Barrier walls relied on sheer mass to provide structural strength, resistance to heat transfer, and water infiltration protection.

So now designers are faced with the challenge of choosing from all these materials to specify a sustainable wall that performs to today’s exacting energy codes and in which all the materials perform together, even though they are made by a wide variety of manufacturers who don’t test their products for compatibility with other company’s products.

Let’s shed some light on which of the most commonly used materials are compatible with each other, either from a materials composition or functionality standpoint, and should never be used together.

Brick and Mortar

The brick and mortar of the outer wythe must be matched to provide a look that matches the designer’s vision plus a combined compressive strength that supports the wall’s weight and any other materials attached to it. Bricks are typically locally manufactured, so brick appearance and strength selection will vary depending on the raw materials used and each manufacturer’s processes. Standard clay brick and lightweight brick using materials such as fly ash are available. Please consult your local brick manufacturer to determine the right types of brick to specify for each job.

Brick Ties and Stone Anchors

A variety of ties are available for cavity walls to link the outer wythe to the structural wall. The most effective are 3-part systems that consist of a barrel explicitly engineered for the cavity width with a screw designed to penetrate the specified structural backup wall such as concrete masonry units (CMUs), or steel or wood studs with sheathing; a plastic clip that acts as both a thermal break and a dissimilar metals break; and the wire tie, which can be Hot-Dip galvanized or stainless steel.

Stone anchors must be custom manufactured and are typically made from stainless steel to avoid galvanic responses between the ties and minerals in the natural stone. Cast stone, which is concrete, does not require stainless steel. Still, given the small cost difference relative to the cost of anchor failure, stainless should be the only choice because it eliminates compatibility problems.

Wire Reinforcement

Ladder-type or truss-type horizontal joint reinforcement is used in CMU structural walls to provide lateral stability. Truss-type reinforcement may be incompatible with CMU walls with full or partially grouted cells, not because of a materials issue, but because the cross-wires can interfere with vertical rebar placement and grout flow. Minimum wire thickness is nine gage or .1483 inches, and mortar bed thickness must be at least twice the embedded wire thickness.

Be sure to specify stainless steel, hot-dip galvanized after fabrication, or epoxy coated wire to avoid in-wall corrosion. Ladder-type wire reinforcement may be formed in a way that spans the cavity, either with solid wire or with eyes designed for use with separate pintles, so it acts as both CMU reinforcement and a brick tie. It is highly recommended that ladder-type wire reinforcement that does not extend past the CMU backup wall exterior be used in combination with the separate brick anchors described above because they allow greater movement in the wall and provide a very effective thermal break.

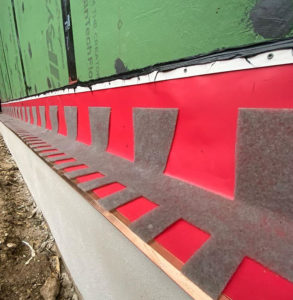

Air- and Water-Tight Washers

For maximum energy efficiency, use 2-inch diameter plastic washers with the brick tie barrel anchors when penetrating rigid insulation (RI) in the cavity to help seal out air and moisture while permanently attaching the insulation. One manufacturer’s washers also have pre-spotting prongs that embed into the insulation for easy on-the-wall veneer anchor assembly and attachment through the RI and into the substrate. Two manufacturers of washers, ties, and fasteners have tested their products to be compatible and are also components in a complete wall system in which all components, including Weather resistant barriers, mortar dropping collection, wall flashing, pre-formed corners, and end dams, and weep vents are proven compatible and have passed is systems tested to NFPA 285 standard.

With all the components available to the designer and builder in today’s masonry cavity walls, it can be time-consuming. Still, it is very important to verify that all selected components are compatible with each other for material performance and functionality and with the environment in which they’re installed. Fortunately, in a few cases, manufacturers are now offering tested wall systems in which multiple components have been proven compatible are available, making the designer’s job faster and less risky.

Compatibility Letters

Letters of compatibility are requested regularly by contractors that want to make sure that what they are asked to do by the architect or the engineer will offer long-term performance for the owner. This also offers long-term performance for the contractor. The performance of combined products and how they react typically should fall on the designer’s shoulders, but it often falls on ours. Here is an example, “Can I get a letter stating that it is okay to put EPDM flashing directly against a bituminous fluid-applied air barrier (generic for this example), will there be a reaction to either product”? Here is how this works, as the manufacturer of the flashing product, my product touches the bituminous air barrier. I cannot write the letter confirming that there is no compatibility problem unless I contact the air barrier manufacturer, share our products’ chemistry, and explain all of the project’s details in question. So, this must be submitted with the original contractor’s request. Next, the air barrier company may throw out the comment…” We have not tested this” (Oh, this drives everyone nuts…) and “we cannot verify the use of the product.” Now we have an issue we need to deal with ourselves as contractors. We must then go to published technical data, product overview, and SD sheets to see if we can determine each product’s chemical properties. Unless we have verification from another project, it becomes difficult to get a letter. So, what is a contractor to do? Ask the question first if there are any compatible products available for use in their application. Sounds simple, but we often chase a rabbit down a rabbit hole to find out that a simple change in the product can get the originally requested letter.