It appears that there still is a need for ballistic resilient construction as long as some members of the human race feel compelled to express themselves through violence. In a word: terrorism of any scale or size. This isn’t a political treatise; it is just a statement of fact given the times we find ourselves in.

Fortunately, there are reasonably effective systems and materials that are available today, right now, should an owner or association, school board, or governmental entity decide a more robust or hardened, facility is needed. These types of facilities are not necessarily for the sole protection of individualsor groups of individuals, such as schools, patrons in commercial facilities, or workers in manufacturing buildings, but for the protection of a plethora of other high value assets – people or “things”.

Ballistic protection may be desired for facilities such as battery storage facilities; critical telecommunications facilities; electrical power grid switching facilities; police stations; military barracks; guard stations; homes or “safe rooms” within homes for diplomats, heads of corporations, heads of governments, or monarchies; water, oil, or natural gas pump stations; precious metals or precious gems retail stores or storage facilities; banks; broadcast facilities in unfriendly environments; biologic agent storage, toxic and poisonous chemical storage; to name a few. Ballistic resilience may be desired or required for basically any facility that houses or contains any person, persons, material, or materials that could have a significant detrimental impact on large groups of individuals or communities if a facility is breached or could have significant impact to the economy, or for facilities that can be breached for illicit gains by terrorists – ransom of people or things.

This is a masonry magazine, so, of course, we are promoting and promulgating the advantages of masonry as a robust and resilient material. There have been several tests or demonstrations that show that typical 4” nominal depth fired clay brick veneer generally resists impacts from low energy munitions from handguns fairly successfully. There, however, have not been many tests of ballistic resistance for higher energy munitions, or “long-barrel“ munitions like .223 (5.56 mm), 7.56 mm (.308), 30-06, 9 mm, or .50 caliber. This is because there isn’t currently a ballistic testing protocol that has been developed for testing the ballistic resistance of masonry walls.

To circumvent this testing “void” Interstate Brick created a producer specified masonry wall ballistic testing protocol that is based on four national standard ballistic tests. The testing included 17 different munitions from .22 Long Rifle to .50 munitions, including three 12-gauge shotgun munitions. Two previous articles in this magazine from 2019 documented that testing process. Those articles profiled 8416 Armor® Brick from Interstate Brick, which passed all munitions testing.

Of course, the durability and munition resistance capability of the brick depends on the clay and the kiln firing curve. Clay varies from manufacturer to manufacturer, based on what is close to their manufacturing facility. Firing methods used in brick kilns also vary from manufacturer to manufacturer. One cannot assume that because the brick from one manufacturer will perform the same as any other brick from any other manufacturer due to the variabilities of the raw material and production processes. So any testing that is done is generally specific to a particular brick from a particular manufacturer.

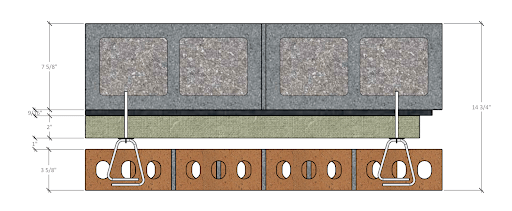

Special ballistic blankets made of various materials, usually consisting of woven layers of high impact-resistance fibers, can be added to a typical wall section, as seen in Figure No. 1 below, to provide a ballistic rated wall. In the assembly in Figure No. 1, a ballistic blanket was added as an addendum to a job in response to some design changes after the initial design was complete. One might speculate that this design change may have been precipitated by some mass shooting event. Regardless, the ballistic blanket was added behind the exterior wall insulation on the exterior side of a CMU wall that was faced with clay brick veneer so as to not affect the aesthetics of the construction, presumedly. The Figure No. 1 wall assembly is comprised of (from inside surface, outward): CMU + WRB + ballistic blanket + exterior insulation + brick veneer with brick ties. The ballistic blanket, depending on the ballistic resistance level, may cost from $10 to $47 per square foot, or more, which is a significant cost to the wall system. It is not known if there are any difficulties with installing brick ties that have fasteners that would need to penetrate the ballistic blanket in order for the veneer to be secured to the CMU backing wall. Electrical conduit may be in the CMU wall if that wall has outlets or switches, which would not be uncommon.

Figure No. 1

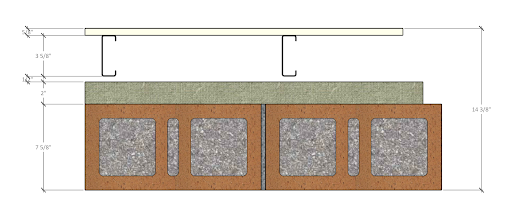

As an effective and cost savings solution Armor® Brick produced by Interstate Brick could have been incorporated in the exterior wall assembly, as shown in Figure No. 2, in lieu of the assembly depicted in Figure No.1. In the Figure No. 2 alternate wall assembly, a single wythe ballistic rated reinforced brick wall would provide the desired aesthetic appearance while simultaneously providing the ballistic resistance, the weather barrier, air barrier, and mass wall, which would then be finished with the interior light gage steel stud wall (22-gauge to 25-gauge steel studs) insulation and interior (painted) gypsum board finished surface. Electrical distribution is simplified when utilizing the steel stud framed wall. The wall in Figure No. 2 is about the same overall thickness, provides equivalent or higher ballistic safety, and provides similar thermal performance as the wall assembly depicted in Figure No. 1.

Figure No. 2

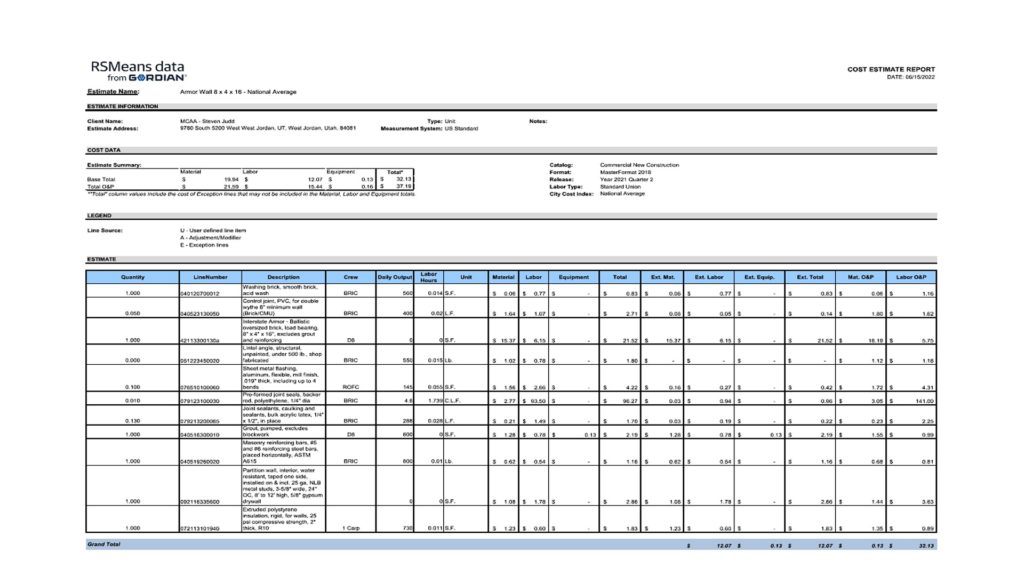

Cost comparison will vary across the US depending on labor wages, shipping costs, and cementitious materials costs, which vary significantly these days, from month to month. National Average costs for these two wall options would be as follows, using RSMeans data, based on subcontractor costs: $48/SFfor the wall assembly represented in Figure No. 1 – includes $10/SF for the ballistic blanket, material only, and labor to install it. Ballistic blankets can cost upwards of $50/SF alone, material only, depending on the level of ballistic resistance, so the figure of $48/SF is likely a somewhat low-end estimate; and $32/SF for the Armor® brick wall, as represented in Figure No. 2 – includes solid grouted walls. Solid grouted walls provide the highest-level ballistic protection per national ballistic test protocols. Overall wall thickness is roughly the same as for the Figure No. 1 assembly. As one can see, the elimination of the brick veneer and the elimination of the ballistic blanket, and using a single wythe Armor® brick wall can create a significant cost saving ($16/SF [or more, depending on the cost of the ballistic blanket]) for the same or even better ballistic performance level. The steel stud framed wall in figure No. 2 would be much easier to run electrical conduit for an added savings not included in the numbers discussed herein.

What if there was no ballistic requirement? The brick over CMU wall cost would drop to around $34/SF, while the single wythe Structural Clay wall would come in around $26/SF if reinforced the same as the CMU wall. One can easily see the cost benefit of a single-wythe structural brick wall over a two-wythe brick over block wall system if brick is the desired aesthetic.

Besides the ballistic performance attributes of a ballistic rated masonry wall system, the single wythe reinforced hollow brick wall also provides the added benefits of a fire rated wall system (up to a 4-hour fire resistance rated wall when filled with non-combustible material), a projectile resistant wall meeting FEMA requirements for tornado shelters (when grouted solid), sound transmission reduction in the neighborhood of 50 dB (when grouted solid) while maintaining the aesthetics and the long term durability and lower maintenance of fired brick

Ballistic resistance provided by Armor® Brick can be a viable and beautiful solution for the protection levels needed for High Value Asset facilities while providing many other performance enhancements along with lasting beauty.

RSMeans Data