Mortar Mixers and Delivery System Purchasing Mistakes (and How to Avoid Them)

Words: Cass Stern

Words: Cassandra Stern

Photos: EZG Manufacturing

Delivery systems are a must on any jobsite, so MASONRY spoke with Steve Wheeler, Sales and Business Development Manager at EZG Manufacturing, to get some insight into the common mistakes mason contractors make when investing in a new mortar mixer or delivery system, as well as the important features, to compare and consider before finalizing the purchase.

Whether you’re in the market for a new mortar mixer or delivery system you will want to brush up on these tips and things to avoid when considering investing in a new piece of equipment. While you may think the first question you should ask yourself is about your budget, you may be surprised to learn that there are actually a few considerations to determine before getting to that crucial step.

Common Misconceptions Regarding Mixers

Before taking the time to research different mortar mixers, first examine if the investment is even necessary in the first place. “Whether you are looking at a mixer or the various delivery systems, when you begin the process, look for the additional benefits and features, not just the price,” advises Wheeler straightaway. “Ask what features will help you reduce your labor time, decrease workplace injuries, and save you money?”

Time and time again, mason contracting companies have made the mistake of renting (or purchasing) equipment for a specific project, only to learn later on that the rental price was overinflated or the equipment is only needed a few times a year. One of the most common misconceptions when purchasing a mixer specifically is that more often than not, a contractor will require a different mixer for different types of materials. This is simply not the case!

“A quality mixer will be able to handle multiple materials,” Wheeler explains, so “when looking for a mixer, look at the material they can mix.” Companies like EZG Manufacturing produce both portable and stationary mixers that can accommodate multiple materials with ease including mortar, grout, and concrete. By investing in a mixer model that can handle multiple material types, mason contractors can save time and money while increasing efficiency on the jobsite immediately and over time.

Another common misconception regarding mortar mixers is that mixers are unable to control dust on the jobsite while in use. Again, not the case! If there is a mortar mixer in use on the jobsite that lacks dust reduction grate options, then it is a good idea to think about replacing it with a more modern model. This advice applies to both solo and field mixing, and should not be forgotten when considering a new masonry mortar mixer.

Delivery System Do’s and Don’ts

If your mason contracting company’s delivery system has recently kicked the bucket (or is a bucket), those days of back-breaking work are over! One important consideration when examining new delivery options is to think about how the investment will potentially improve efficiency on the jobsite. “Delivery systems have made major advancement over the years, and the days of using 5-gallon buckets are in the past,” agrees Wheeler, who recommends a quick cost-savings analysis for those hesitant to take the plunge on a (potentially expensive) investment in new equipment like a delivery system.

One common adage is “if it ain’t broke, don’t try to fix it.” While it may be tempting to continue to try and work around the need for new equipment in an effort to save money in the short term, it’s inevitable that making the investment will improve productivity and profitability immensely in the long run. “The initial cost of a delivery system may seem high,” Wheeler says, “but when you calculate the time being saved by increasing the amount of grout you can place in the wall, the reduction of people to grout the wall, and the money saved in fewer workplace injuries, the initial cost now seems insignificant.”

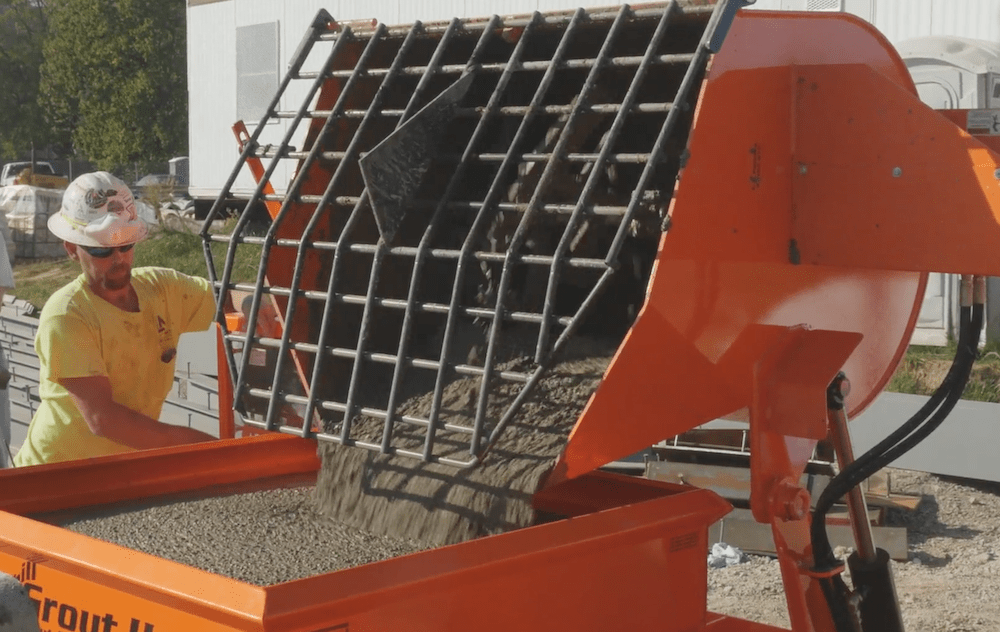

The Grout Hog from EZG Manufacturing is a great example of the new and innovative delivery system types worth considering for an upcoming investment. Featuring a unique swivel base, the Grout Hog allows masons to grout up to 17 feet of a wall without moving the forklift, reducing grouting from a job that requires multiple laborers to one needing just two workers. This, in turn, frees up space, time, and money for future or other concurrent projects- all of which are great returns on investment for the bottom line.

How to Choose the Best Mixer

Did you know that “only 30% of the costs of a piece of equipment is incurred the day it is purchased, while 70% is incurred during everyday use combined with its lifespan?” With this in mind, Wheeler notes, “a contractor should look for quality and ergonomics for the price he or she is paying.” But what exactly does that mean? When arriving at the product comparison stage of new equipment shopping, price is but one of many considerations to keep in mind. While a lower-cost mixer option may be attractive initially, it could turn out to be a much more expensive option down the road- especially if poor quality and design wear out faster and require costly repairs.

Here are a couple of pieces of advice to keep in mind when comparing mixers:

- When looking at mixers, a contractor should note the drum thickness as thin gauge steel can wear holes in the drum in a few months.

- It is important to check mixer blade quality. Low-quality rubber will tear and need to be replaced often, resulting in more downtime.

- Check for reversible paddles as an additional feature. Even the best operators may forget to add enough water, and without the reverse option, the mixer will plug.

Selecting the Right Delivery System for You

Delivery systems have their own set of considerations when weighing a purchase, the first of which is to determine how much material will need to be placed. Then and only then options can be compared fairly and accurately based on their features and specifications. For example, Wheeler says, “The Grout Hog takes the place of pouring grout with five-gallon buckets when small quantities of grout (under six yards at a time) are needed.”

Information like this is important to have on hand when making a purchasing decision for many reasons, especially because it is essential to help choose the right delivery system for your mason contracting company’s unique project needs. If your company typically takes on smaller projects, a larger delivery system may be an unnecessary expense. Conversely, a smaller delivery system may underperform on a larger project and cause unnecessary delays.

The inclusion of a grout pump is yet another determining factor when choosing a delivery system. While not always necessary, grout pumps are especially helpful when working with large amounts of grout and can be an effective tool in grouting a masonry project. Grout pumps are an added expense, but, as Wheeler explains, options like “EZG Manufacturing’s Hog Pump uses a hydraulic S-tube which results in safer operation and less maintenance,” further adding to the overall return on investment.

The final factor to keep in mind when selecting a delivery system is the size as well as the height requirements for an average project. For projects exceeding a certain height, scaffolding may be an inadequate solution in terms of worker safety and efficiency. Other projects simply cannot facilitate traditional scaffolding due to rough terrain, in-climate weather, or other environmental factors.

For jobs like these, says Wheeler, “a contractor may need to utilize a crane to place the grout where it is needed.” If that is the case, he recommends an option like the “Grout Hog with the crane bail added, which will save time and be more efficient.” Be sure to go with the delivery system option that best accommodates the needs of your mason contracting company, and you won’t be disappointed.

There are hundreds of different makes, models, and sizes available when it comes to mixers and delivery systems, and starting the purchasing process can seem daunting or even intimidating, but it doesn’t have to be! Remember to ask questions, do your research, and if you can visit a showroom to check out the equipment you are considering in person. With a little bit of effort and time spent, any mason contractor can easily find the right mixer or delivery system for their unique needs.